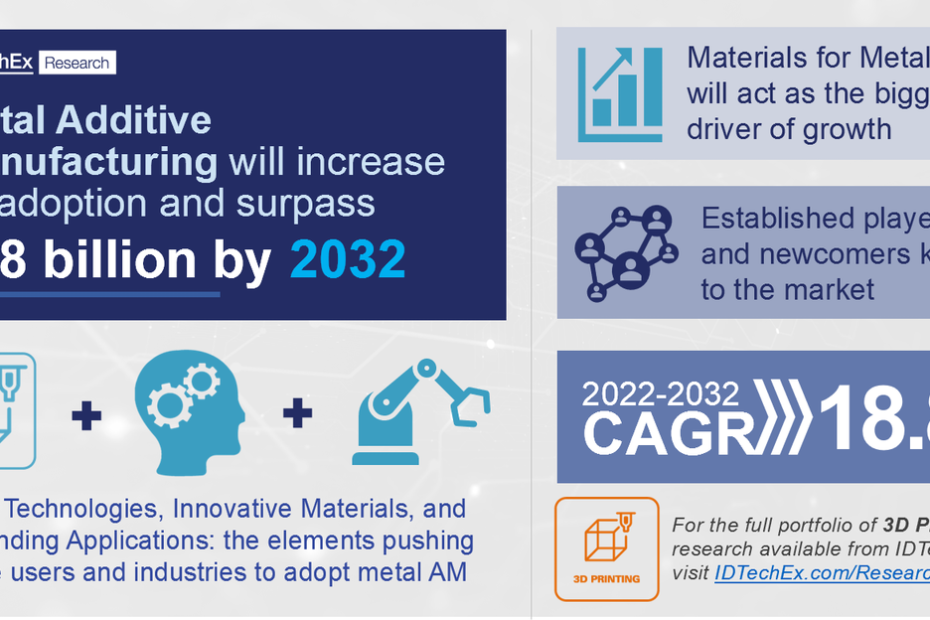

SAMANTHA – 36 months after: main results and successes

SAMANTHA project aims to develop a novel training program addressing the mismatched high-tech T-shaped skills for proper implementation of AM in the value chains of such sectors through high qualified workers. In IO1 partners conducted several surveys addressing experts working wether in the Toolmaking industry and the Habitat sector in order to find out mismatches and knowledge gaps. Moreover, teachers’ and students’ feedback were also important and a comparison was done in terms of analyzing the current VET training offer… Read More »SAMANTHA – 36 months after: main results and successes