The second intellectual output of the SAMANTHA project is SAMANTHA Joint Curriculum and Training Content

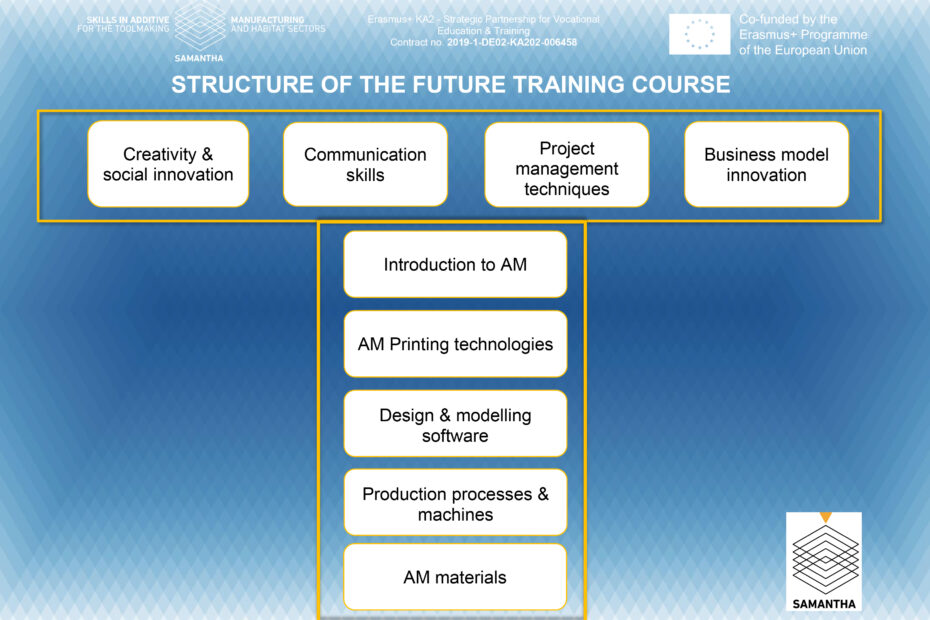

The features of SAMANTHA initiative defined and analysed the most suitable training paths, modules and units in order to ease the learning process of the future students who will have different levels of knowledge and areas of expertise and they will want to choose those subject matters in which they are more interested in. The main goal of the IO2 is to obtain the most suitable curriculum and, therefore, the offline training content considering the real needs of the target… Read More »The second intellectual output of the SAMANTHA project is SAMANTHA Joint Curriculum and Training Content