On 18th February 2022, TECOS held via MS Teams platform the first webinar of the pilot phase for the project SAMANTHA.

The webinar was split into two parts. The first part has been dedicated to the official pilot phase launch by presenting the SAMANTHA platform, and in the second part TECOS presented the three webinar speakers. Before the end a simple Q&A section was held.

The three speakers were:

– Matic Vogrin – mechanical engineer specialized in Additive Manufacturing (3D printing) of Metals in direct connection with tool industry. He is currently working for the company – MARSI group.

– Simon Erban – expert in Additive Manufacturing and Toolmaking sector. He is currently working for the company – MARSI group.

– Matjaž Milfelner, a lecturer at the College of Industrial Engineering in Celje, an expert in the field of Additive Manufacturing printing technologies.

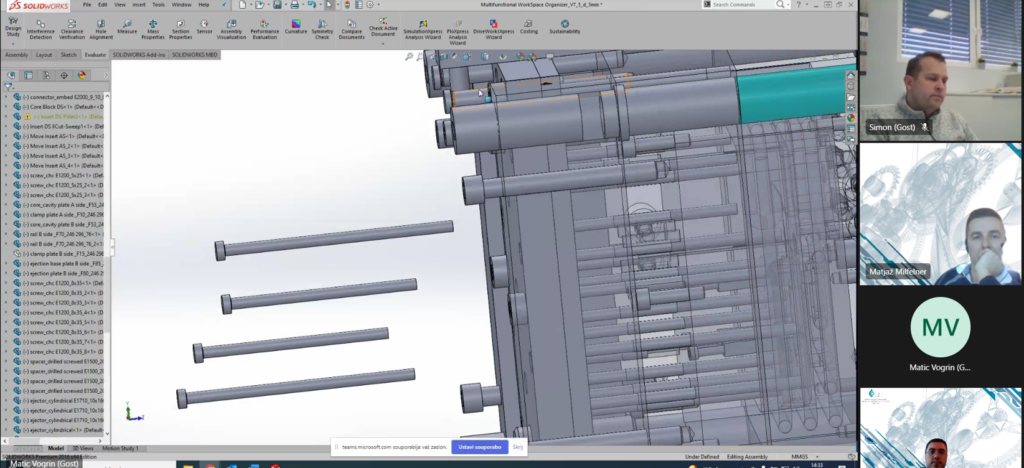

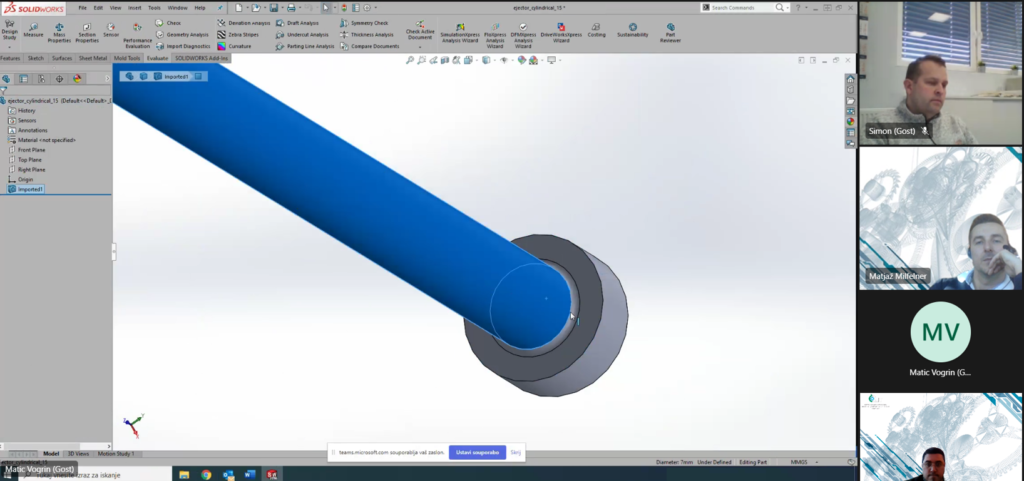

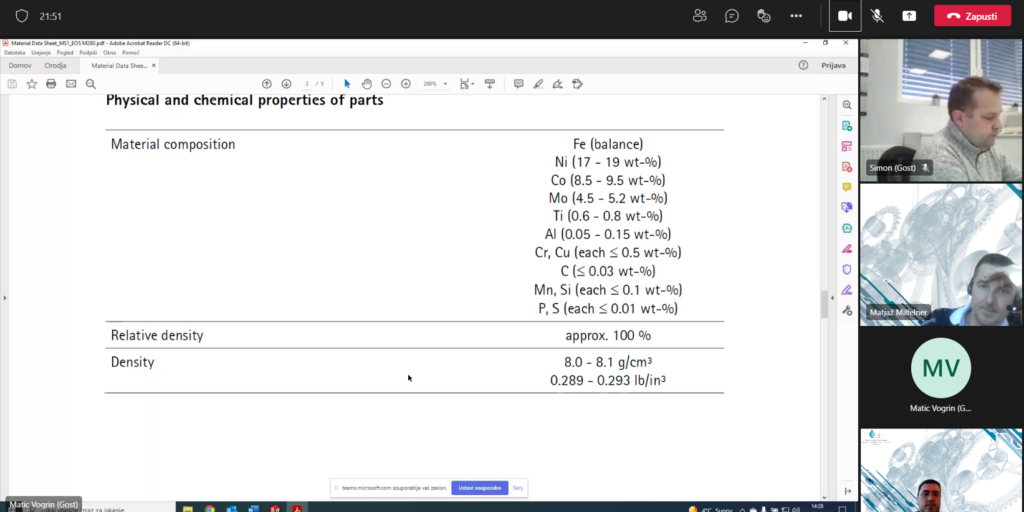

First speaker was Matic Vogrin, who brought the participants in the world of metal materials suitable for 3D metal printing especially on DMLS technology. He presented how Additive Manufacturing can be used to print different tool components that can be practically used in Toolmaking sector and how to obtain the precision by fine tuning the laser parameters before actual 3D printing of metal part. He has shown many past examples of printed metal components for the tool sector that can be easily manufactured with technology.

The second speaker was Simon Erban who presented the state-of-the-art EOSINT M280 machine for 3D printing of metallic materials. As an expert in in Additive Manufacturing and Toolmaking sector he showed the complex parts that were printed and used in Toolmaking sector. He showed with help of printed parts how important it is to gain different skills in AM printing technology in order to use the right material and technology and 3D print complex technical part that can be directly used in Toolmaking sector. Lots of practical working hours in front of EOSINT M280 machine is needed to gain and expend the practical knowledge and skills in 3D metal printing, which is applicable to Toolmaking sector.

The third speaker was Matjaž Milfelner an experienced lecturer who is active at the College of Industrial Engineering in Celje, and who professionally works at TECOS. With his long-term expertise in the field of Additive Manufacturing printing technologies and metal materials he reflected on potential of 3D metal printing and overall advantage of AM process. He presented different AM printing technologies with help of videos and pointed out the advantage and disadvantage of individual AM printing technologies.

Finally, the webinar ended with the round table led by Dragan Kusić from TECOS. Based on the raised questions, direct practical answers were provided in relation to the SAMANTHA project objectives were given, especially on AM technology selection to 3D print the metal part with adequate metallic material in order to reach the needed tolerances, which is a more common problem in Toolmaking and Additive Manufacturing sector.

All mentors who took part in this webinar were available for any clarifications on the topics related to SAMANTHA project and on the pilot phase that project partners will conduct.

Some highlights from the test phase:

For further information visit the project website.